This app calculates Sphere, Hemispherical Head or Hemi Head, Dish End Petal type layout Development required in plate or sheet metal lay-outing used for fabrication. it is also called Flat pattern development of Sphere or Hemispherical Heads.

This app used for petal lay-outing of Vessels End Caps. it is used in spherical type storage tank fabrication. it is used in heads or dish ends or vessel cap fabrication of pressure vessels.

It is recommended to used mean dimensions for lay-outing for higher accuracy and ready to used fabrication layouts.

Unit Setting Options available for mm/inches

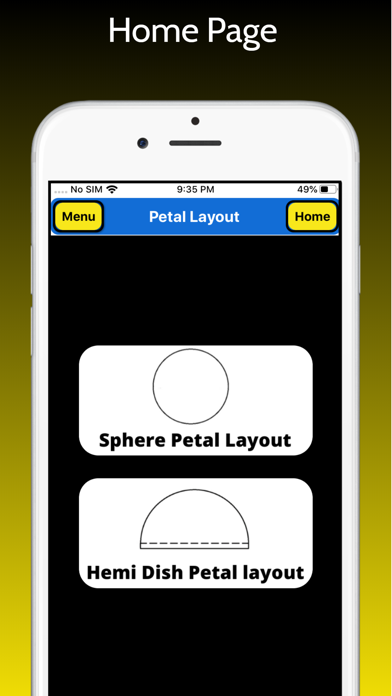

In this app we had following shapes Petal Layout Developments:

1. Hemispherical Head

2. Sphere

we had provided three options for petal lay-outing as 12 parts layout, 24 part layouts, 48 part layouts.

Hemi Head Petal Layout : In this Petal Lay-outing option we can layout for Hemispherical Dish end or Vessels Cap Petal layout Development required for fabrication of Pressure vessels heads or vessel end cap. in this layout we required input dimension as head or Dish end Diameter in mm and Straight Face in mm. We have 12 parts, 24 parts, 48 parts options for petal layout development. In Out put of this we will get all dimension required for fabrication layout marking.

Sphere Petal layout : In Sphere Petal Lay-outing We can calculate dimension required for fabrication lay-outing of Sphere fabrication. In sphere type layout you need to enter input dimension as Diameter in mm and after selecting 12 parts, 24 parts, 48 part layout option for generate fabrication layout dimensions.

This application best suited for Petal type layout development of sphere or hemispherical Dish ends. It is used in Storage tank fabrication Pressure Vessels fabrication.

This is very helpful for Fabrication Fitter, Fabrication Engineer, Production Engineer or any other working professional in the field of Process equipments fabrication.

Key words : Petal type layouts, Sphere Fabrication, Hemi Dish End, Dish End, Vessels End Cap, Pressure Vessels Fabrication, Petal Fabrications, Sphere Layout, Fabrication, Process

Equipments, Flat Pattern Layout.